What to Do Once Partial Discharge Is Detected

01 / 08 / 19

Blog

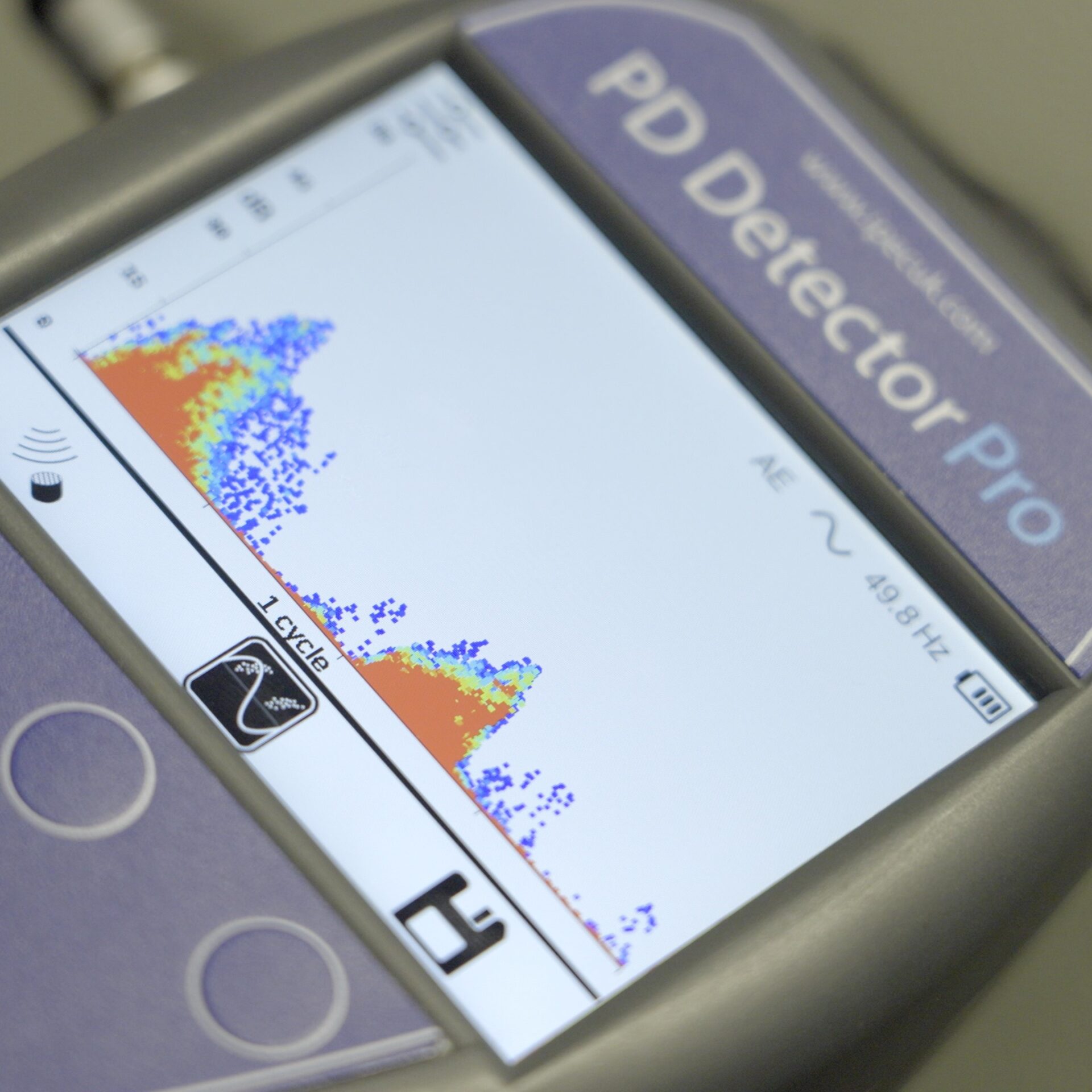

There is no escaping the fact that partial discharge is a complex phenomenon. The first step is to identify partial discharge activity, then to decide on the best course of action to take once partial discharge is detected. Both phases will require an experienced individual or consultant. But of course, it’s difficult to know what to do when you don’t have that experience yourself – the answer is simple: ask an expert! That’s why we sat down with PD expert and consultant Martin Judd of High Frequency Diagnostics and Engineering to discuss some principles from his experience of partial discharge measurements. In our previous post, Martin talked us through his ‘TLC Checklist’ for diagnosing PD. This time around, Martin shares his advice on what to do once PD is detected.

There is no escaping the fact that partial discharge is a complex phenomenon. The first step is to identify partial discharge activity, then to decide on the best course of action to take once partial discharge is detected. Both phases will require an experienced individual or consultant. But of course, it’s difficult to know what to do when you don’t have that experience yourself – the answer is simple: ask an expert! That’s why we sat down with PD expert and consultant Martin Judd of High Frequency Diagnostics and Engineering to discuss some principles from his experience of partial discharge measurements. In our previous post, Martin talked us through his ‘TLC Checklist’ for diagnosing PD. This time around, Martin shares his advice on what to do once PD is detected.

What is your advised course of action once partial discharge is detected?

Establishing an appropriate course of action once partial discharge is detected requires not only expertise in PD measurement, but experience of the type of asset being monitored. This is because the costs of erroneous diagnosis can be considerable. The process usually works best when the PD expert collaborates with a plant technical specialist to develop a plan of action. This may range from ‘do nothing’, through ‘schedule investigative maintenance’ to ‘intervene immediately’.

The fire analogy

In my experience, the most common issue once partial discharge is detected arises from the understanding and expectations of the HV asset owner/operator. In this regard, I like to use fire as an analogy for PD: “There’s a fire in the house – what should we do?” Is there a problem or not? Consider the images below. If the fire is in a location where it can spread, damaging and consuming materials, immediate action is essential. On the other hand, if it does not present an immediate threat, we just need to be careful and ensure that it remains under control. Sometimes a large PD can be relatively benign if it is in a non-critical location, while a small PD can sometimes pose an imminent threat of insulation breakdown.

A question that frequently arises in relation to unconventional PD measurements (i.e., those which don’t quantify PD in pC as stipulated in IEC60270) is, “What is the discharge equivalent to in pC?”. It’s rarely possible to read across to pC in this way because all measurements of PD (including the IEC60270 method itself) give a reading that depends strongly on the location of the PD relative to the sensor or measurement point at which it is detected. Since a pass/fail threshold in pC often applies to factory acceptance testing of HV apparatus, it is understandable that users expect to be able to take the same approach in the field, but unfortunately this is rarely possible. This emphasises the importance of the ‘TLC Checklist’, which takes a more holistic view of the insulation health when equipment is in service.

Continuing the analogy with fire, compare the two images below. If we focus only on a particular measurement of the flames, such as height (which is a nice quantifiable measure in metres), we might state with confidence that the flames on the right are 50 times bigger than the flames on the left. However, if our main concern is integrity of the property, the small fire beside a log cabin poses a much higher risk than a group of trees burning next to the stone castle. Hence the task of PD diagnosis is primarily one of risk assessment, in which information we have about history and context can be more valuable than an absolute measurement of PD magnitude.

IPEC specialise in the design and manufacture of partial discharge monitoring and testing solutions for the power industry. Our PD products range includes Portable Switchgear PD Testing Instruments, Cable PD Testing Systems, Permanent PD Monitoring for MV, HV and EHV systems and our range of PD Sensors. Visit our product page to find out more about our PD monitoring solutions.